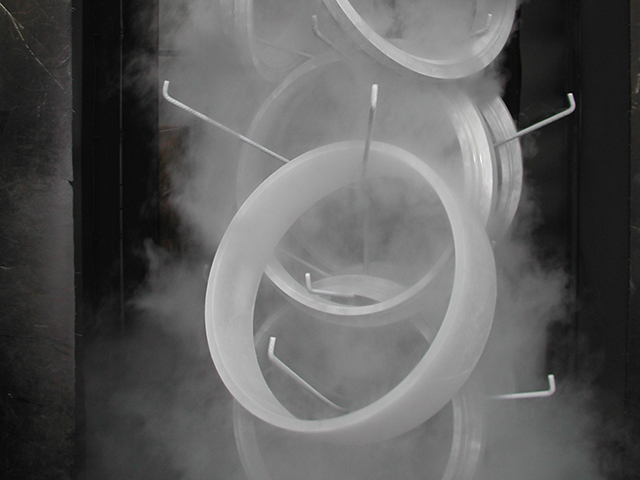

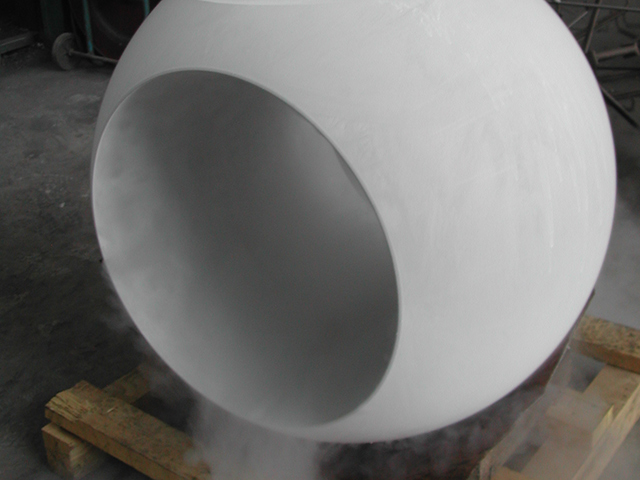

CRYO TEST FOR LARGE DIMENSION BALL VALVES

Cryogenic treatment for the transformation of residual austenite in steel.

The cryogenic treatment of high-alloyed and carburized steels is a further step in the induced hardening process with heat treatment.

This process takes place in a thermal range between -70 and -120 ° C, and completes the transformation of the austenite into a more compact and hard martensitic structure. The hardness of steel increases as the martensitic component increases. At the same time, usury resistance also increases, which is in a positive exchange ratio

with hardness (corrosion resistance also depends on the presence of carbides).

A percentage of residual austenite may be desired in certain applications (e.g. involute bearings or transmissions) that require precise plastic characteristics of the metal in order to allow it to absorb the stresses of impacts and twists.