Tunnel

Linear tunnel interventions – V6 100

The following operations were completed:

Intervention details

| Tunnel modernization |

| Installation of inlet suction hood |

| Installation of tunnel security closure |

| Safely equipment manipulation |

| Safe exclusion protection for maintenance |

| Damaged pieces reconstruction |

| CE plate installation |

Linear tunnel interventions – V4 100

The following operations were completed:

Intervention details

| Tunnel modernization |

| Exhaust extraction hood application |

| Modification of protection covers for conveyors |

| Rationalization of the electrical panel |

| Conveyors replacement |

| Damaged parts replacement |

| Certified on-off valve installation |

Linear tunnel interventions – TPC6 106

The following operations were completed:

Intervention details

| Nitrogen spray systems adjustment |

| Electrical panels adaptation |

| Cryogenic testing |

| Cryogenic operation optimization |

| Creation of cryogenic dosing systems |

| Protection cover production |

| Proportional valve revision |

|

CE plate installation wings |

Linear tunnel interventions – SB3 Conveyors

The following operations were completed:

Intervention details

| Equipment adaptation to changed necessities |

| Tunnel functionality recovery |

| Replacement of unsuitable parts |

| Equipment status evaluation |

Cryo-boxes

Interventions on Cryobox

The following operations were completed:

Intervention details

| Electrical panel adjustment |

| Cryogenic spurt and extraction system adaptation |

| Missing components supply |

| Advanced security systems installation |

| Box-O2 Analyzer interface |

| modification and strengthening of the structures |

| Important parts reconstruction |

| Replacement and standardization of components |

Spiral freezer with cryogenic refrigerators

It is a freezing spiral, the frigories of which are obtained by spraying nitrogen cryogenic gas on the product to be frozen, completely built in AISI 304 stainless steel. The freezer consists of:

■ An insulated box where freezing takes place

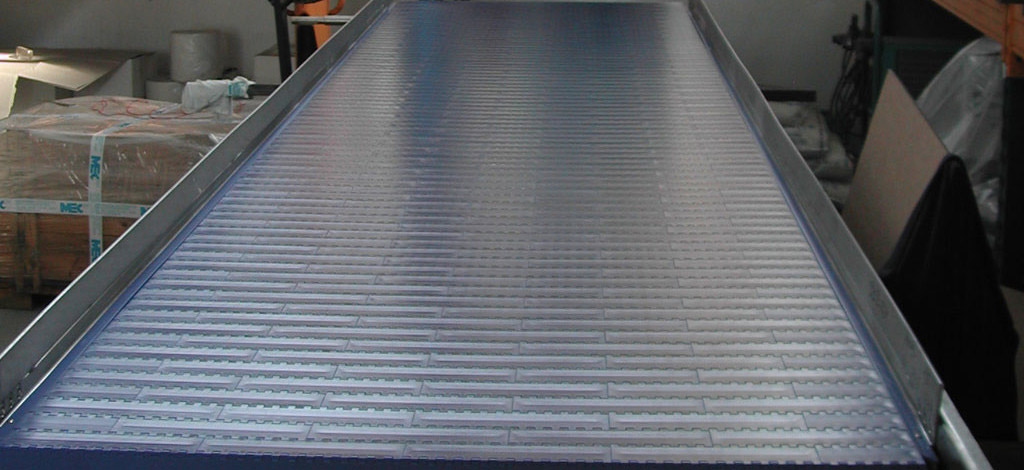

■ A conveyor belt placed inside the cold box

■ A system for regulating and distributing the liquid nitrogen to be sprayed on the product

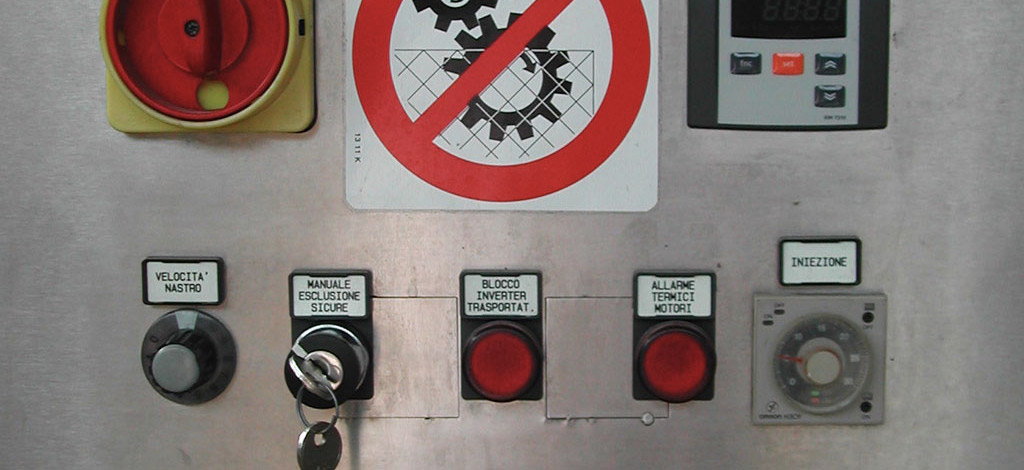

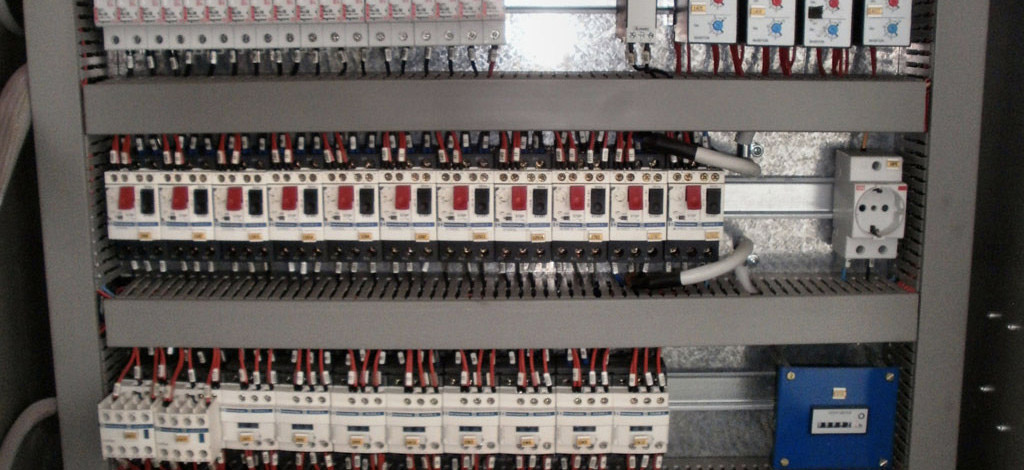

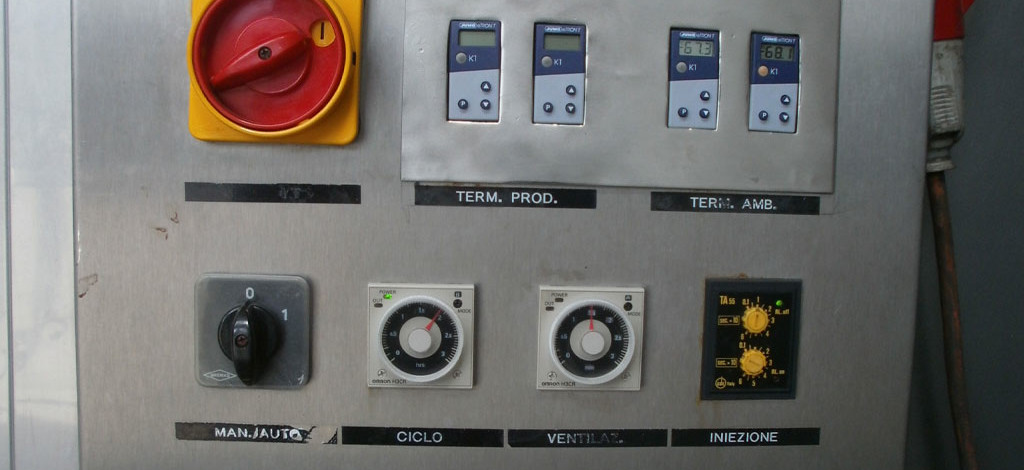

■ An electrical panel with centralized system controls

The cold box of the freezer is made with walls in stainless steel sheet with the interspace insulated by polyurethane foam with a thickness of 120 mm.

This type of construction, as well as allowing thermal excursions in the range from +50°C to -90°C, prevents the infiltration of water and other substances into the cavities of the walls.

The box is equipped with manual opening doors that allow access to the inside to allow quick and easy cleaning and sanitation of the system, as well as to allow any maintenance to be carried out. The floor is equipped with predetermined drainage points to allow the collection of washing and defrosting water, so as to make disposal easy and ecological.

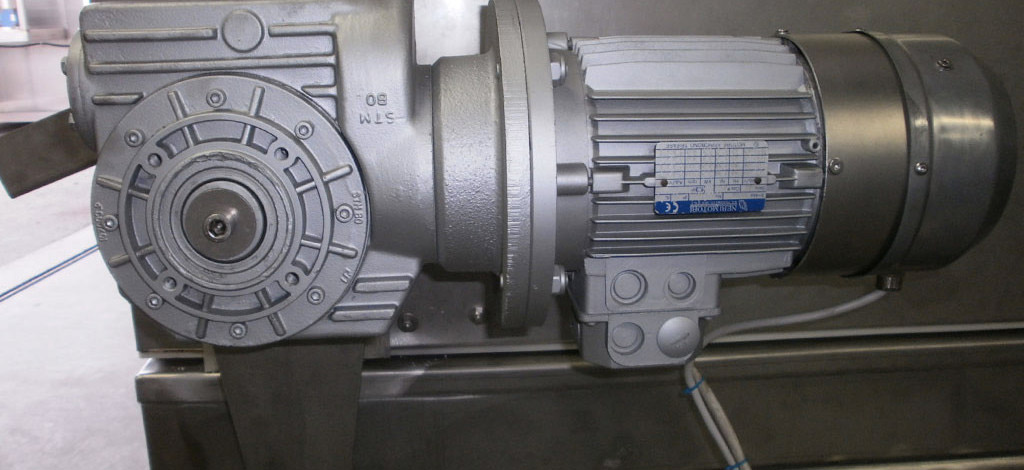

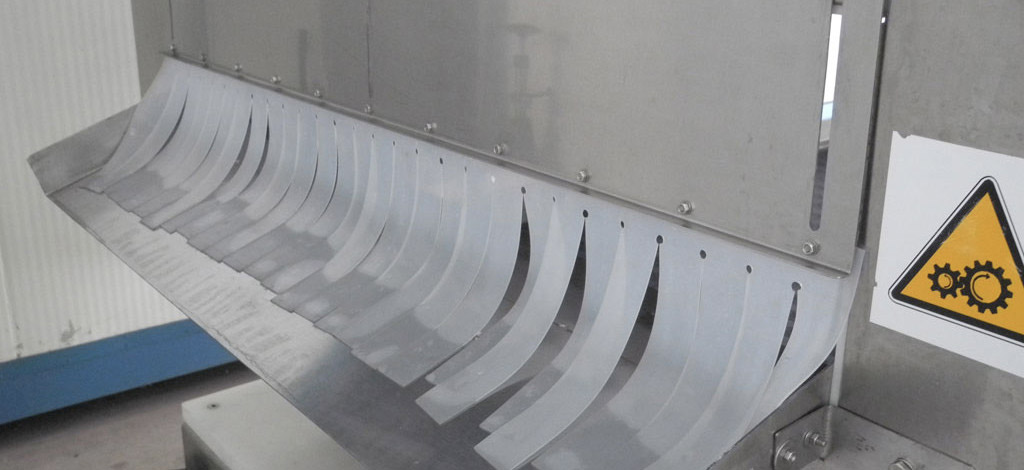

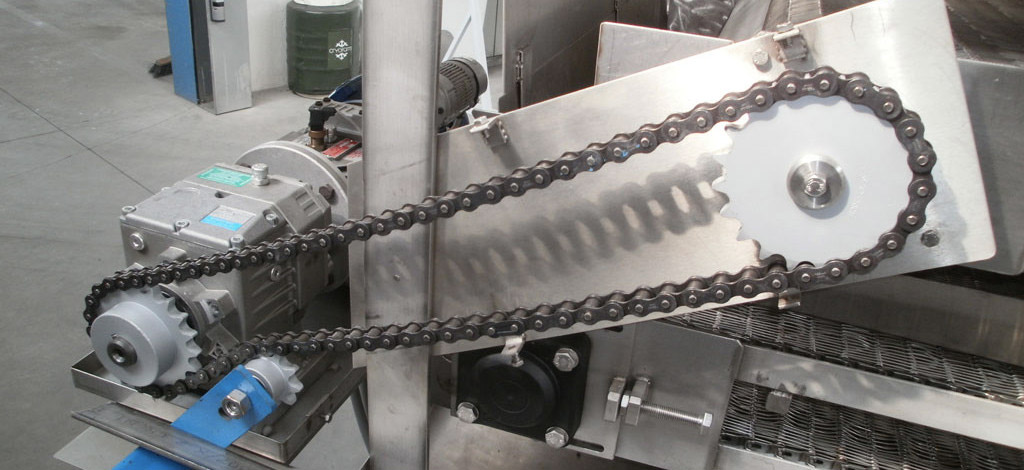

The conveyor belt positioned inside the box follows a circular spiral-shaped path and is dragged by a watertight drum, totally devoid of movement mechanisms inside the cell.

The construction of the belt sliding system is performed with AISI 304 stainless steel. The AISI304 stainless steel conveyor is complete with towing chains and a device for automatic adjustment of the compensation of thermal excursions.

The definition of the center distance, length and width of the conveyor is designed in relation to the production needs and the type of product to be frozen.

The speed of advancement of the conveyor belt is adjustable within a project range and can be read on a digital indicator located on the electrical panel.

All components are in pickled and passivated stainless steel.

The gas distribution system is made with stainless steel pipes with calibrated holes or alternatively calibrated nozzles that allow the cryogenic liquid to be nebulized on the product. The quantity of gas sprayed and the internal temperature of the box are detected by PT100 and regulated by a modulating cryogenic valve.

The electrical panel in stainless steel, IP65 with plexiglass protection window, without PLC.

The temperature is controlled by a thermoregulator.

The conveyor speed is controlled with an inverter and the data is shown on a display.

The safety circuit includes a flashing light, an alarm siren and emergency stop buttons. As an optional alternative, the plant can be managed using a PLC.

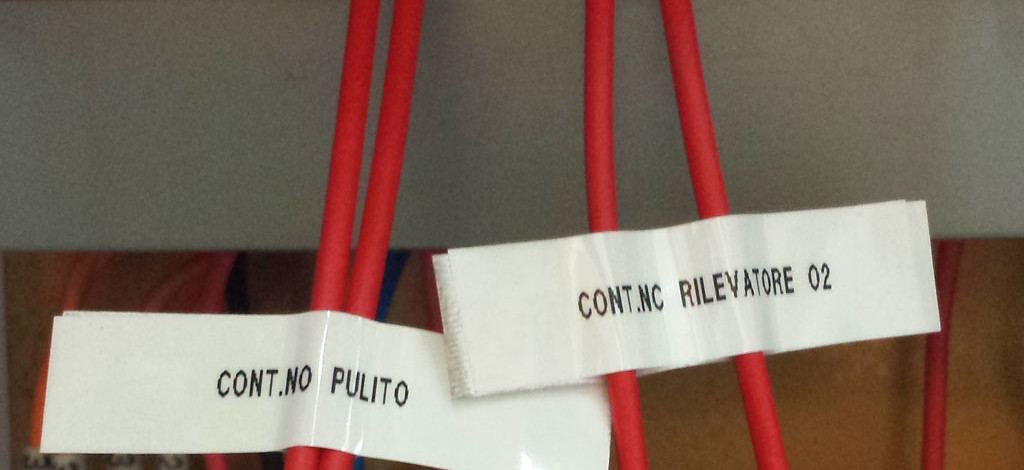

Safety elements Proximity switches and electrical contacts available both for connecting an O2 concentration alarm and for providing clean fresh air.