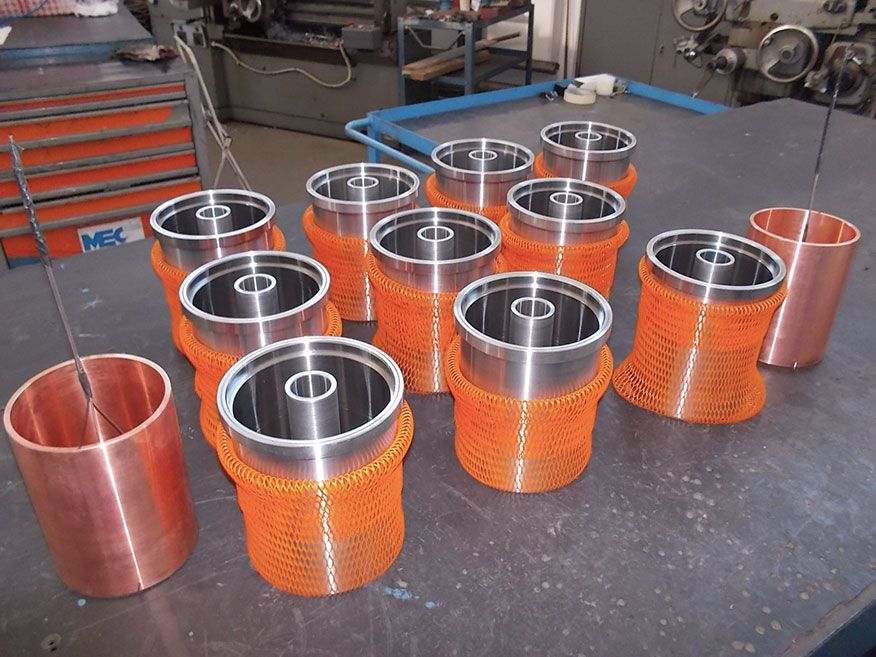

COLD SHRINKING

What is the cold shrink fit process?

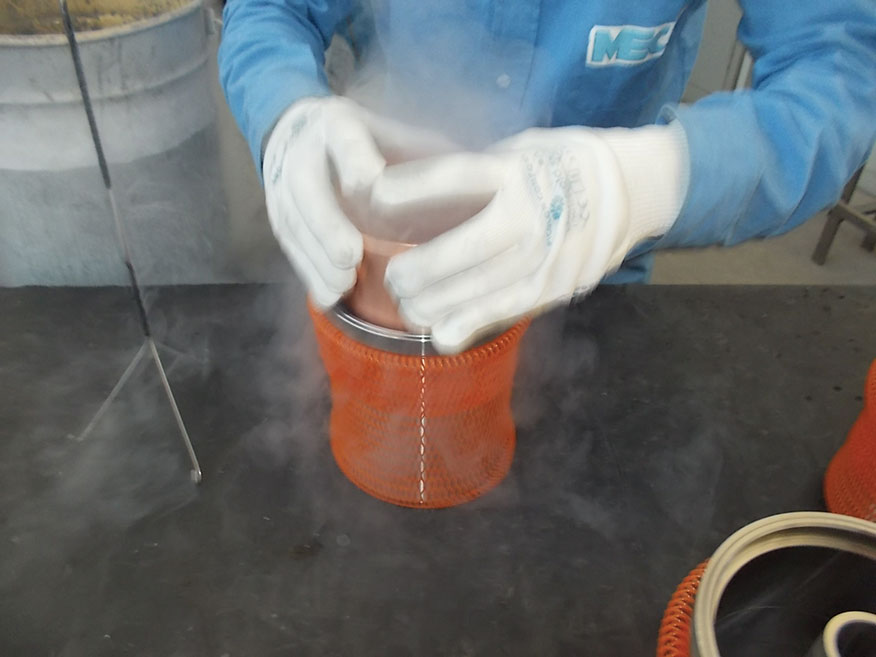

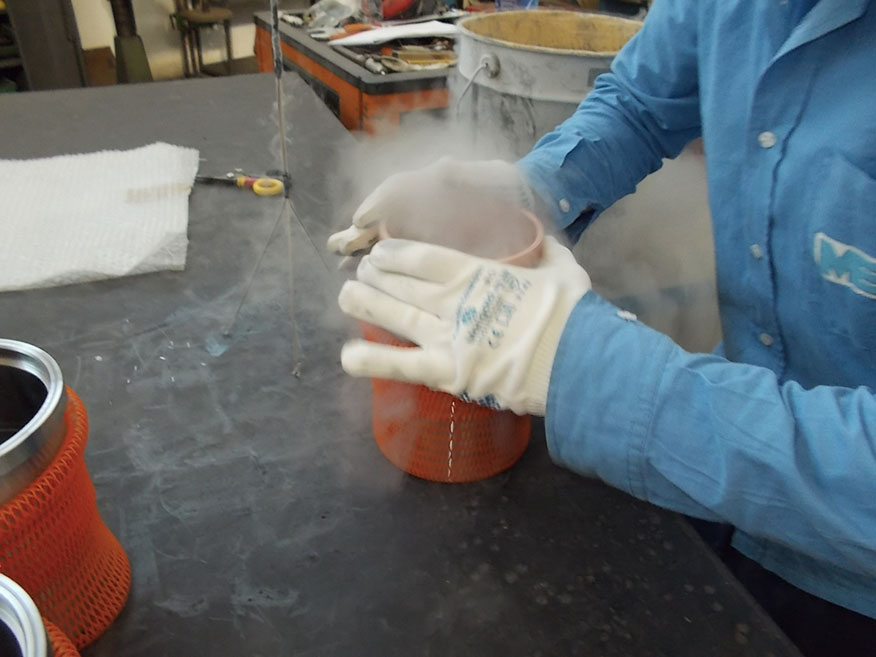

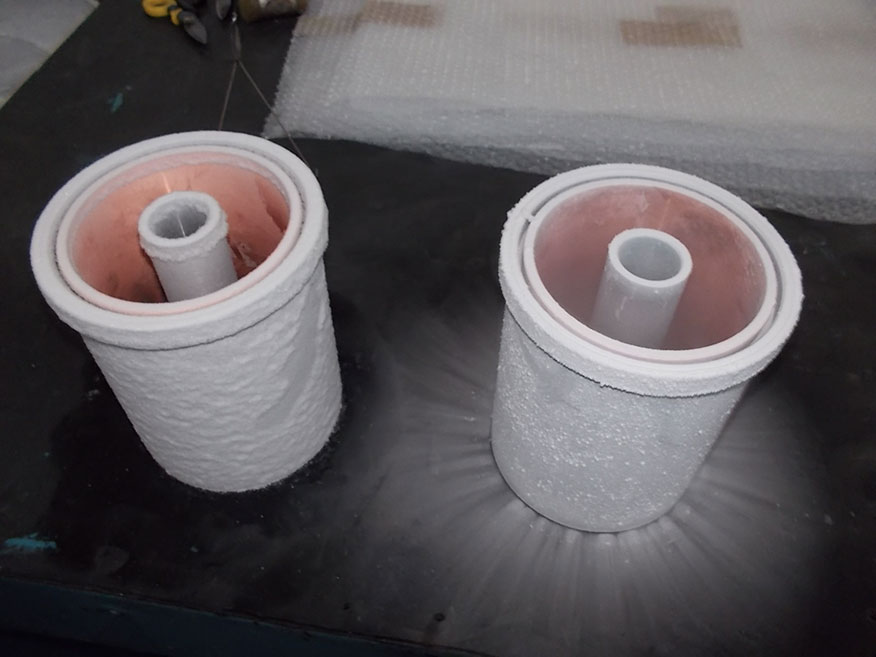

Cold shrinking, using liquid nitrogen, results in the joining of two shaped elements in such a way that they are complementary in order to form an interlocking weld. Cryogenic keying with liquid nitrogen at -196 ° C has assumed great importance in the construction of transmissions and gearboxes for the purpose of coupling between shafts and sprockets.

What does cryogenic shrink fit apply to?

Cryogenic shrink fit can be used for single or series production: valve seats and guides, for example, can be automatically keyed into cylinder heads or liners, crankcase and gearbox.

What are the advantages of cryogenic shrinking?

The advantages of cryogenic keying are particularly evident where shafts, collars and similar components are coupled with relatively big levers, gear wheels or housings, or in cases where the interference seats must be very solid.

In summary:

❄︎ Higher coupling strength than a press fit.

❄︎ The structure of the material and the geometry of the components remain unchanged.

❄︎ Cold-shrinked elements do not form oxidation layers.

❄︎ It is a very simple and quick assembly technique that can also be used on site.

❄︎ The investment costs are very low.