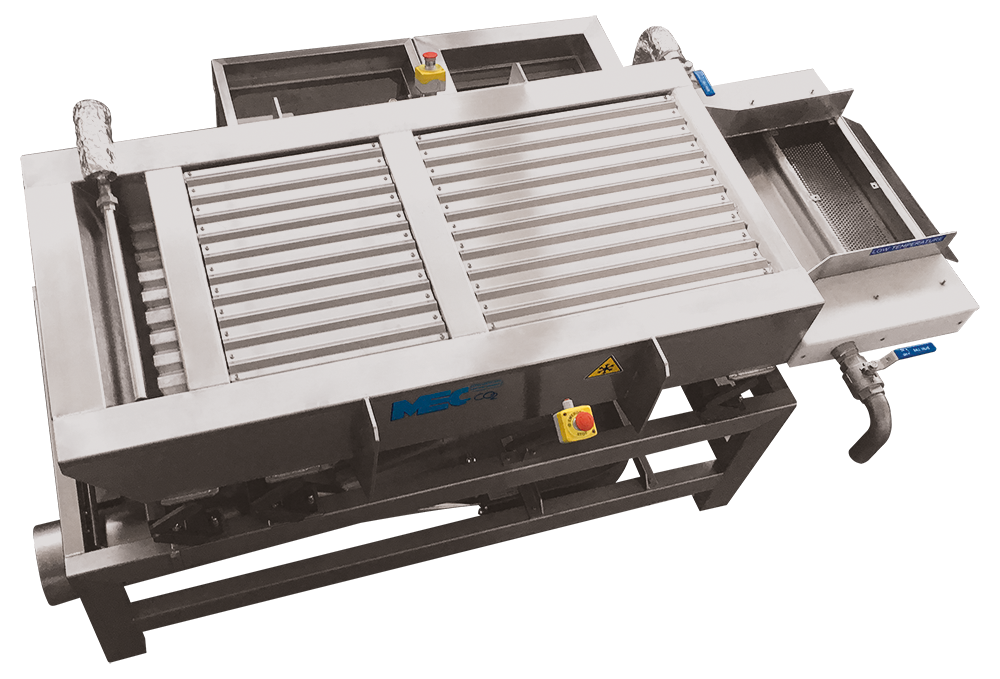

ENCRUSTING MACHINE WITH LIQUID NITROGEN

What is the MECCRIOS liquid nitrogen crisper used for?

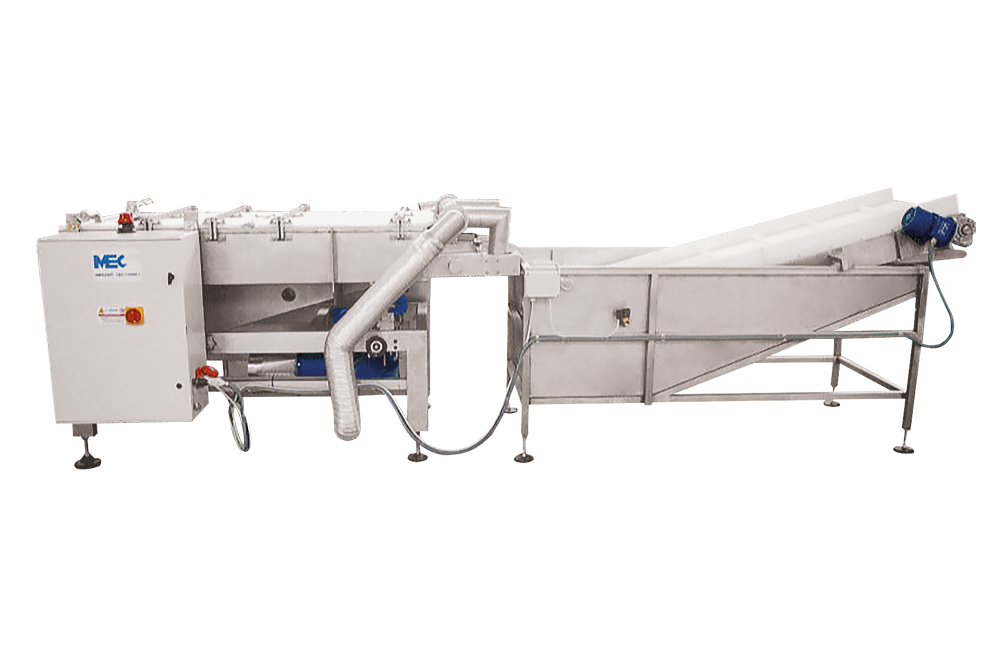

The liquid nitrogen crusting machine is used in the fields: food, pharmaceutical, and industrial to crust and freeze solid, semi-dense, and liquid products through the use of liquid-phase nitrogen. It can also be used as pre-freezer to support gaseous or mechanical freezing tunnels.

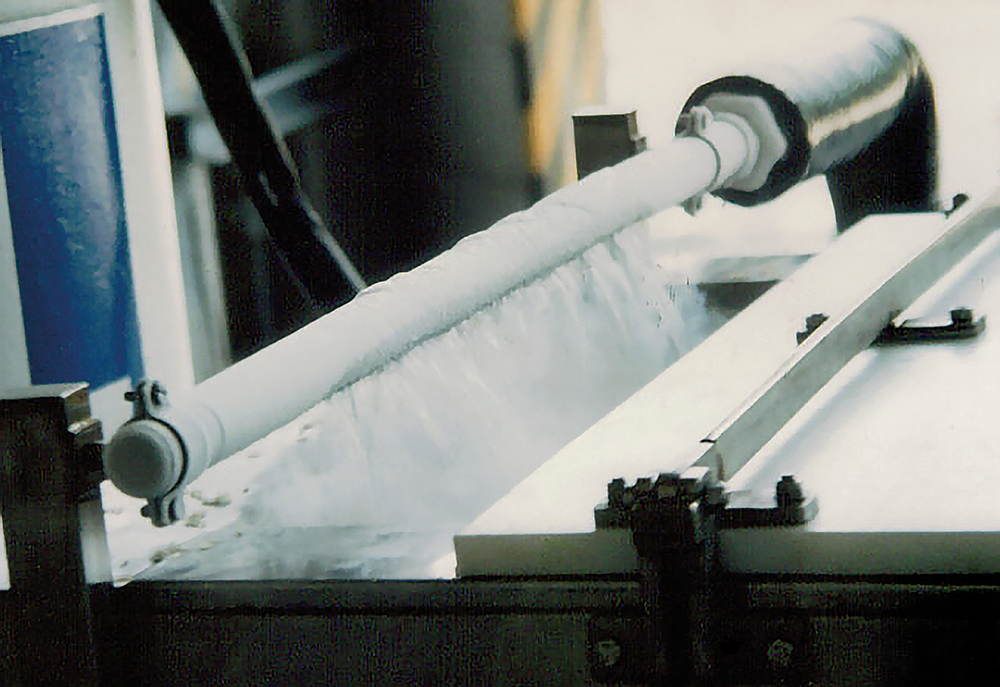

The unit is easily adjustable, and the direct contact between the products and the extremely low temperature cryogenic fluid inside a vibrating container with linear movement allows almost immediate freezing of the product surface. Cryogenic fluid consists of nitrogen, a non-toxic, non-harmful and inert gas, which because of these characteristics can be used safely.

The vibrating tank, in which the liquid nitrogen is contained , is moved by vibrators, whose frequency varies according to the speed to be given to the treated product, or the contact time between the product and the cryogenic fluid itself. The contact time, which can be adjusted according to the angle between the direction of the vibratory movement and the surface of the tank, the length of the tank itself and its inclination, is on average between 10 and 15 sec.

What are the advantages of using the encrusting machine with liquid nitrogen?

The machine is designed to ensure efficiency and sustainability of the crusting and freezing process.

Efficiency: a recycling system, realized with a collecting tank and a cryogenic pump, allows a re-usage of the liquid nitrogen up to its exhaustion.

Sustainability : the quantity of vaporized cryogenic fluid during the freezing process is discharged from the operating zone through an extractor hood and its transferring fan.

Working cycle

1. Filling the process tank with the liquid nitrogen with the feeding from the storage tank (automatic).

2. Manual adjustment of the operating parameters: valve of the liquid nitrogen pump flow rate, frequency of the inverter of the vibrators to vary the speed of advancement of the product, exit of the rod of the jacks to vary the inclination of the tank and its relative thickness, of liquid nitrogen.

3. Arranging temperature of the unit with liquid nitrogen circulation only for 10 minutes.

4. Feeding of the product to be crusted.

5. End of feeding of the product to be crusted.

6. After 2 minutes, liquid nitrogen supply is interrupted.

7. After 60 sec. interruption of all unit functions and discharge of liquid nitrogen from the process tank.

8. When the temperature of the unit has returned to that of the environment, cleaning and washing can be carried out if necessary

MecCrust MC 1.5-1.000 model

Diagonal pieces< 100 mm

Liquid nitrogen film thickness approx. 5 mm

Vibration frequency 40/60 Hz

Movement range 0.3 / 15 mm

Inclination angle -2 ° / + 4 °

Contact time< 15 sec

The plant on which the productivity data were collected and which we propose as a standard are:

Liquid nitrogen film thickness approx. 5 mm

Overall dimensions 2.000 × 1.600 × 1.300 mm

Nitrogen tank dimensions 1,500 × 1,000 mm

During practical tests carried out in collaboration with customers we have obtained extremely interesting results especially when compared with the compact dimensions of the equipment.

Liquid nitrogen film thickness approx. 5 mm

Apple cubes 1,000 kg / h

Lentils 720 kg / h

Berries 250 kg / h

Strawberries 180 kg / h

Slices of kiwi 600 kg / h

Boiled rice 850 kg / h